Picture this: You’re designing a high-speed manufacturing line where precision isn’t just a luxury—it’s the heartbeat of your operation. One hiccup in tension control could mean miles of wasted material or hours of recalibration. Enter the unsung hero of industrial motion control: the hysteresis brake. This isn’t your granddad’s friction brake; it’s a silent, wear-free maestro conducting symphonies of smooth deceleration. Let’s pull back the curtain on this engineering marvel.

WHAT MAKES HYSTERESIS BRAKES UNIQUE?

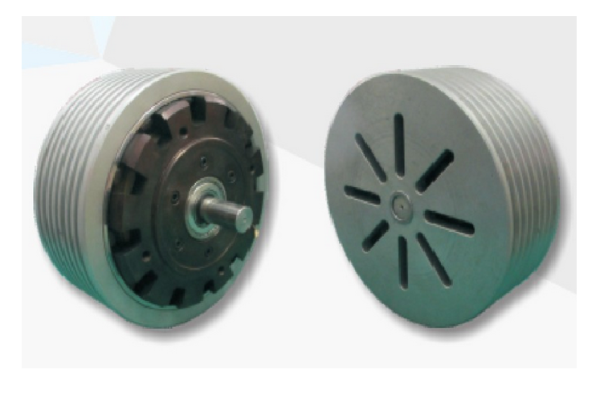

At its core, a hysteresis brake harnesses electromagnetic principles—no physical contact, no friction pads, zero wear and tear. When electricity flows through its coil, it creates a magnetic field that “drags” against a rotor made of special magnetic material. The resistance? That’s hysteresis loss—energy dissipated as heat when magnetic domains realign. The genius? Torque is exquisitely proportional to input current. Dial up the amps, torque rises linearly. Dial down, it ebbs gracefully. No jerks. No spikes. Just velvet-smooth control.

Imagine controlling tension on a 0.001mm optical fiber or regulating speed in a medical centrifuge spinning at 20,000 RPM. Traditional brakes would shudder, overheat, or degrade. Hysteresis units? They operate coolly, consistently, indefinitely.

THE SECRET SAUCE: APPLICATIONS THAT SHINE

Aerospace Testing Simulators

When engineers test satellite components in zero-gravity simulations, hysteresis brakes replicate cosmic resistance with micron-level accuracy. Vibrations? Nonexistent. Consistency? Unwavering. One aerospace client cut calibration downtime by 70% after switching from eddy-current brakes.

Packaging Powerhouses

Ever wonder how snack wrappers fly through machines at 500 units/minute without tearing? Hysteresis brakes maintain perfect web tension. Too loose? Chocolate bars crumble. Too tight? Foil snaps. With hysteresis, tension stays exact—rain or shine, shift after shift.

Robotics \u0026 Cobots

Collaborative robots (cobots) handling delicate tasks—like inserting microchips—demand feather-light braking. Hysteresis units offer “touch sensitivity” no clutch can match. Sudden power loss? They fail-safe gently, preventing $10,000 wafers from becoming confetti.

Medical Marvels

In MRI machines, hysteresis brakes position patients without magnetic interference. Surgeons rely on them in robotic arms for tremor-free incisions. Even dialysis pumps use them to regulate blood flow within 1% tolerance. Lives literally hinge on their silence.

THE NUMBERS DON’T LIE (BUT THEY DO IMPRESS)

Let’s talk specs. A typical hysteresis brake:

Operates from -40°C to 150°C

Achieves torque consistency within ±1%

Responds to input changes in under 10ms

Lasts 100,000+ hours with zero maintenance

Compare that to friction brakes shedding particulate dust or pneumatic systems guzzling compressed air. Hysteresis brakes sip power, exhale reliability.

BEYOND BRAKING: THE UNEXPECTED PERKS

Heat? Friend, Not Foe

While traditional brakes overheat and fade, hysteresis units dissipate heat evenly. Some even integrate liquid cooling for extreme loads. One steel plant uses them in red-hot rolling mills—where oil-cooled hydraulics would burst into flames.

Silence Is Golden

Ever stood near a factory floor? The screech of friction brakes is industrial tinnitus. Hysteresis brakes? Library-quiet. Audiophile-grade turntables use them for buttery-smooth platter stops—because even vinyl deserves a graceful exit.

Customization Kingdom

Need 0.01 Nm of torque for a lab scale? Or 200 Nm for a cable winch? Manufacturers like Magtrol or Placid Industries tailor hysteresis brakes like Savile Row suits—size, torque curve, even connector types.

THE \"BUT WHAT ABOUT...?\" CORNER

Cost? Yes, hysteresis brakes carry a premium upfront. But crunch the math: Eliminate replacement pads, reduce downtime, slash energy costs. ROI often clocks in under 18 months.

Complexity? Wiring is simpler than pneumatics. One power lead, one control signal. Integrate it with a PLC using off-the-shelf drivers.

Limitations? Peak torque caps around 500 Nm. For Titanic-sized loads, hybrid systems (hysteresis + friction) steal the show.

REAL-WORLD WINS: CASE SNIPPETS

Wind Turbine Techs Rejoice

A wind farm in Scotland replaced hydraulic yaw brakes with hysteresis units. Result: 40% less maintenance on 300-meter towers. No more icy climbs to replace leaky valves.

Printing Perfection

A German press operator running metallic ink jobs eliminated “ink splatter” during emergency stops. How? Hysteresis brakes decelerate rolls in perfect sync. Wastage dropped by 15% overnight.

3D Printing’s Quiet Revolution

High-end printers use hysteresis brake s to control filament feed. Layer misalignment? Gone. The subtle *hum* of a midnight print job now soothes insomniac engineers.

YOUR MOVE: EMBRACE THE FUTURE

Still clinging to creaky friction brakes? It’s like using a sundial in the age of atomic clocks. Hysteresis technology isn’t just an upgrade—it’s a paradigm shift.

Whether you’re orchestrating nanoscale biotech or mega-watt renewables, the message is clear: Control shouldn’t mean compromise. Demand silence. Demand precision. Demand immortality for your machinery.

Ready to transform motion into magic? The engineers at TorqueTech Innovations crafted a hysteresis brake that saved a space rover mission last year. Their motto? “Zero Contact. Zero Doubt.” Fitting, don’t you think?

Explore. Experiment. Elevate. Your machines will thank you—in whispers. 🔧🚀

[Closing Note: This article merely skims the surface. Connect with hysteresis specialists for bespoke solutions—because in precision engineering, “almost” is a four-letter word.]